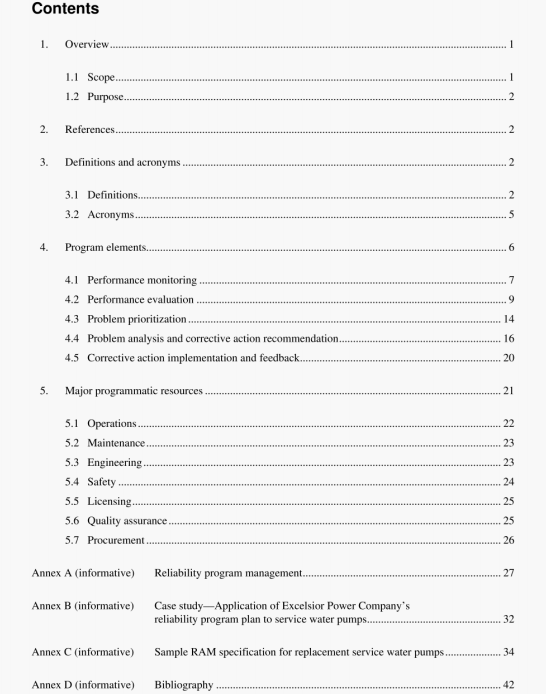

IEEE Std 933:1999 pdf free download.IEEE Guide for the Definition of Reliability Program Plans for Nuclear Power Generating Stations.

Implementation of the performance monitoring task should focus on two concerns: utilization of existing information and expansion or tailoring information-gathering activities to suit the needs of the reliability program. However, first, it should be recognized that peculiar reliability requests may require collection of information not available. All performance monitoring data collection activities should be integrated into overall data collection activities to prevent double counting failures and overloading staff. Addressing these concerns should include consideration of the following items:

a) Much existing information may be stored in an electronically compatible medium (in particular. maintenance records); thus, the information for the performance monitoring task may be easily extracted. However, other types of information (such as the qualitative descriptions of failure or the results of tests conducted to measure equipment degradation like acoustic monitoring and other nondestructive methods are not as easily recorded and extracted.

bI The present and future needs of the reliability program should be carefully assessed when modifying existing information-gathering activities. First, it is desirable to usc a single procedure to document component maintenance and testing, independent of whether the component is included within the scope of the reliability program. This practice simplifies the plant record-keeping effort and allows easy addition of equipment to the reliability program in the future. Second. the level of detail should be balanced so all pertinent information is gathered without collecting an excessive volume of information that will not be utilized IIEEE Std 352-1987. IEEE Std 577-19761. Third. some highly desirable information (e.g.. qualitative descriptions of events, subjective opinions about the causes of failures is transitory; it should be quickly recorded to preserve its quality.

4.2 Performance evaluation

4.2.1 Explanation

Performance evaluation is the qualitativc or quantitative analysis that compares selected event and physical parameter data to plant performance targets, improvement goals. or alert levels to identify deviations from expected performance. This task includes setting both qualitative objectives and quantitative targets. goals. alert levels, or action levels in the start-up phase of a reliability program and routinely conducting both diagnostic and prognostic work to identify current reliability problems and to predict likely future problems. Included in this effort is the specific consideration 01 the validity of any collected historical data set in light of programmatic or design changes that have occurred in the interim. For example. if a previous analysis has indicated a need to change a surveillance interval, the data set collection process should reflect the potential for significant change in the failure rate as a result of this new interval. Detailed inputs and outputs are illustrated in Figure 3.

IEEE Std 933:1999 pdf free download