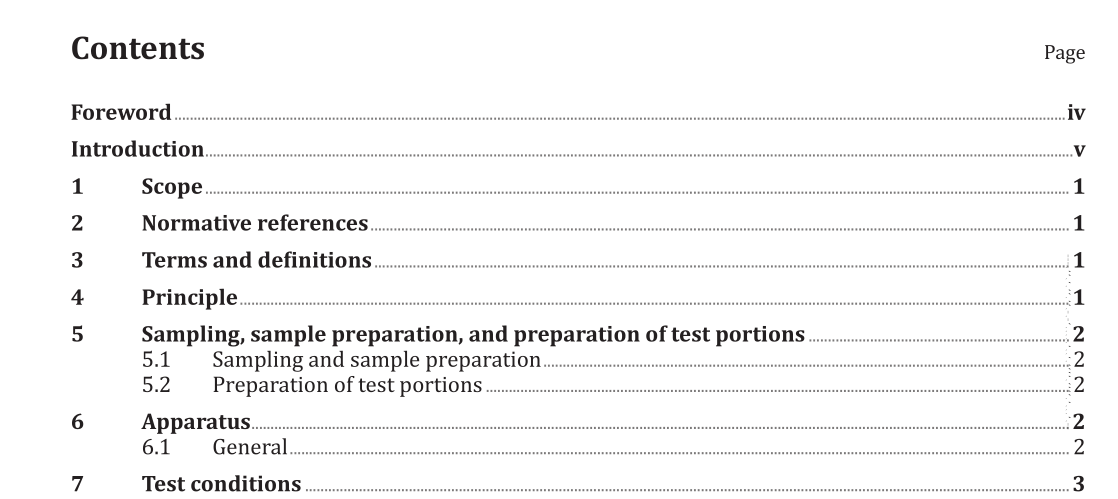

ISO 11258:2015 pdf download.Iron ores for shaft direct-reduction feedstocks — Determination of the reducibility index, final degree of reduction and degree of metallization

1 Scope

This International Standard specifies a method to provide a relative measure for evaluating the extent to and ease to which oxygen can be removed from iron ores, when reduced under conditions resembling those prevailing in shaft direct-reduction processes. It specifies the determination of the reducibility,

final degree of reduction, and degree of metallization.

This International Standard is applicable to lump ores and hot-bonded pellets.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 2597-1, Iron ores — Determination of total iron content — Part 1: Titrimetric method after tin(II)

chloride reduction

ISO 2597-2, Iron ores — Determination of total iron content — Part 2: Titrimetric methods after

titanium(III) chloride reduction

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 5416, Direct reduced iron — Determination of metallic iron — Bromine-methanol titrimetric method

ISO 9035, Iron ores — Determination of acid-soluble iron(II) content — Titrimetric method

ISO 11323, Iron ore and direct reduced iron — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

4 Principle

The test portion is isothermally reduced in a fixed bed, at 800 °C, using a reducing gas consisting of H 2,CO, CO 2 , and N 2 , and is weighed continuously or at specified time intervals until 90 min of reduction is reached. The rate of reduction is calculated at the oxygen/iron ratio of 0,9 and the final degree of reduction is calculated from the oxygen mass loss after 90 min (R 90 ). The degree of metallization is calculated either by a formula based on R 90 or by chemical analysis of the reduced product.

5 Sampling, sample preparation, and preparation of test portions

5.1 Sampling and sample preparation

Sampling of a lot and preparation of a test sample shall be in accordance with ISO 3082. The size range for pellets shall be 50 % – 16,0 mm + 12,5 mm and 50 % – 12,5 mm + 10,0 mm. The size range for lump ores shall be 50 % – 20,0 mm + 16,0 mm and 50 % – 16,0 mm + 10,0 mm. A test sample of at least 2,5 kg, on dry basis, of the sized material shall be obtained. Oven-dry the test sample to constant mass at 105 °C ± 5 °C and cool it to room temperature before preparation of the test portions. NOTE Constant mass is achieved when the difference in mass between two subsequent measurements becomes less than 0,05 % of the initial mass of the test sample.

ISO 11258:2015 pdf download